PTFE Coated Fiberglass Fabric combines the strength and durability of fiberglass with the unique properties of polytetrafluoroethylene (PTFE), resulting in a material that offers exceptional resistance to heat, chemicals, and wear. This makes it an indispensable material in various industrial applications.

This versatile fabric is widely used in sectors such as aerospace, automotive, electronics, and food processing. It serves multiple purposes, including as conveyor belts for food, as insulation in electrical applications, and as protective covers in environments where chemical resistance and thermal stability are required.

This versatile fabric is widely used in sectors such as aerospace, automotive, electronics, and food processing. It serves multiple purposes, including as conveyor belts for food, as insulation in electrical applications, and as protective covers in environments where chemical resistance and thermal stability are required.

PTFE Coated Fiberglass Fabric

PTFE coated glass Fabrics

PTFE coated glass and aramid fabrics that offer a wide range of useful physical properties, no other plastics material can match tis combination of properties.

High temperature resistance (-70℃~+260℃)

Low friction

Outstanding dielectric strength

Excellent chemical resistance

Inherent strength & flexibility

Non-toxic

Non-stick

Excellent release

Resistance to UV and HF

Silicone rubber coated glass fabric

GCTC supply silicone coated fabrics exhibit very similar properties to PTFE fluorocarbon resin and PTFE coated fabrics:

Excellent Release properties up to 230°C

Silicone coated surfaces exhibit excellent release characteristics and will release adhesive and viscous materials which often adhere to a PTFE fluorocarbon resin.

Good Chemical Resistance

Silicone coated fabrics exhibit high resistance to attack from mild alkali, non-oxidizing acids, most salts, mineral lubricating oil, air, moisture and sunlight.

Superior Abrasion Resistance and Flex

Silicone coated fabrics offer a tough coated surface with high abrasion and flex resistance. Silicone coated fabrics, however do not exhibit the low friction surfaces or self- lubricating properties of fluorocarbon resins.

Super Dielectric Properties

Silicone coated fabrics are excellent electrical insulators in tough environments.

Food Grade PTFE coated glass fabric

Food grade, new development Non-stick PTFE coated, closed weave glass fabric is specially design for food cooking industry as delivering innovative customer solutions is our goal. Our food grade fabric is delivering with core characteristics:

High release non- stick surface

Temperature resistance (-73C to +260C)

Outstanding chemical resistance

Excellent fire resistance

Superior electrical properties

Water repellent & anti-staining coatings

Food approved coatings

PTFE coated glass baking fabric

Baking Sheets & Food Preparation

GCTC offers a material suitable for baking sheets for domestic or industrial purposes.

The baking sheet has been designed with the domestic/consumer market in mind. With its ultra-smooth, non-stick surface, even the stickiest foods are sure to lift clean away. These sheets are long-lasting and can be used in the hottest oven or microwave, up to 260°C. The special PTFE coated surface ensures the baking sheet can be used over and over again. Our products can be used for food preparation, lining cake tins, roasting tins, grill pans, baking trays, and even frying pans.

Depending on your preference, products include GC076G (76 microns) and GC013G (127 microns).

Our baking fabric is ideal for cooking buns, cakes, meringues, sticky pastries, biscuits, pizzas and oven chips.

To use any of our baking fabric just simply cut the sheet to the right size and position directly on the baking tray or pan. Then simply place the food on the sheet and cook as usual. After use, wipe clean or wash in warm soapy water. Store flat or rolled, please do not crease.

No pre-greasing or flouring necessary

Simply cut to size with a knife

Environmentally friendly

Easy wipe/wash clean

Dishwasher safe

Fat free cooking

Long lasting

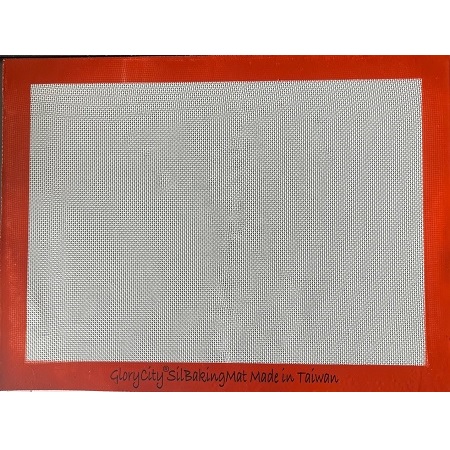

SILICONE BAKING MAT – A must-have kitchen baking accessories for any baker, these silicone baking mats are made with high strength glass fiber grid fabric as substrate and coated with silicone resin as baking sheets provide even heat distribution for food that helps you cook foods more efficiently and get higher-quality baking like a pro.

HEALTHY, NON-STICK COOKING SURFACE – these silicone sheets for baking has premium silicone, and fiberglass design that provides consistent heat distribution and promotes even baking, withstanding temperatures from -40℃to +250 ℃

to make it easier to bake cookies, candies, meats, or even fruits and vegetables without relying on unhealthy flour, fats, oils, or sprays.

PROFESSIONAL RELIABLE QUALITY – Made of food-grade silicone, this silicone baking sheet can be used for baking foods, kneading or rolling dough, creating crispy pizza or French fries, and making healthier foods for you, your family, and your guests with long-lasting reliability.

WASHABLE AND REUSABLE – Our non-stick baking sheet for oven use can be wiped clean with soap water or placed in the top rack of the dishwasher, making it easier to clean and reuse for breakfast, lunch, or dinner recipes. Easily to replace the traditional baking paper and spend no time for cleaning baking trays, our silicone mat makes your nonstick baking easier!

100% SATISFACTION SERVICE – What we want to provide with you is the best silicone cooking sheet with trusted customer service. Any questions, please do not hesitate to contact us, we will make you 100% satisfaction. Meanwhile, we can also provide customized sizes, colors and logos.

Typical Properties

Nominal Values

Thickness (mm)

0.63

Weight (g/m²)

916

Appearance

Butter White Food Grade

Coating (%)

36

Warp Tensile Strength (N/cm)

N/A

Warp Tear Resistance (N/cm)

N/A

Silicone Adhesion (KN/m)

17

Surface Resistance @100V (Ω/Sq)

Insulative

Operating Temperature (℃)

-20to +230

Selecting the appropriate

Temperature Resistance: Ensure the fabric can handle the operating temperatures of your specific application.

Chemical Resistance: Choose a fabric that can withstand the chemicals it may be exposed to during use.

Strength and Durability: Consider the mechanical stresses the fabric will encounter and select a grade that offers the necessary tensile strength and wear resistance.

Q: What maintenance does require?

A: This fabric typically requires minimal maintenance, but regular cleaning to remove any accumulated contaminants can extend its life.

Q: Can be cut to size?

A: Yes, it can be custom cut to specific dimensions, but proper tools and techniques should be used to ensure clean cuts without fraying.

Recent advancements in the products market include the development of new formulations that enhance UV resistance and increase the fabric's lifespan under extreme environmental conditions. These innovations are driving its adoption in new markets, such as renewable energy and advanced manufacturing.

The manufacturing process for involves applying a PTFE coating to woven fiberglass, creating a seamless bond that enhances the fabric’s properties. Quality control is paramount in this process, and leading manufacturers and suppliers use sophisticated techniques to ensure consistent coating application and fabric performance.

PTFE Coated Fiberglass Fabric

involves several critical considerations:Temperature Resistance: Ensure the fabric can handle the operating temperatures of your specific application.

Chemical Resistance: Choose a fabric that can withstand the chemicals it may be exposed to during use.

Strength and Durability: Consider the mechanical stresses the fabric will encounter and select a grade that offers the necessary tensile strength and wear resistance.

Q: What maintenance does require?

A: This fabric typically requires minimal maintenance, but regular cleaning to remove any accumulated contaminants can extend its life.

Q: Can be cut to size?

A: Yes, it can be custom cut to specific dimensions, but proper tools and techniques should be used to ensure clean cuts without fraying.

Recent advancements in the products market include the development of new formulations that enhance UV resistance and increase the fabric's lifespan under extreme environmental conditions. These innovations are driving its adoption in new markets, such as renewable energy and advanced manufacturing.

The manufacturing process for involves applying a PTFE coating to woven fiberglass, creating a seamless bond that enhances the fabric’s properties. Quality control is paramount in this process, and leading manufacturers and suppliers use sophisticated techniques to ensure consistent coating application and fabric performance.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文