UV Long Arc Curing Lamps are essential components in various industrial processes, primarily utilized for the rapid curing of coatings, adhesives, and inks. These lamps harness ultraviolet light to initiate a photochemical reaction that cures materials quickly and effectively.

The versatility of UV Lamps extends to numerous sectors including automotive, electronics, and printing industries. Their ability to cure materials swiftly makes them indispensable in assembly lines and mass production environments where time and quality are critical.

The versatility of UV Lamps extends to numerous sectors including automotive, electronics, and printing industries. Their ability to cure materials swiftly makes them indispensable in assembly lines and mass production environments where time and quality are critical.

UV Long Arc Curing Lamps

Exposure Lamp – Ga type

Typical spectrum output of Ga metal doped lamp

Gallium iodide addition-produces wavelengths of 400Nm and 420Nm, this type of lamp is particularly suitable for curing white pigments, therefor it is usually used in the diazo-type processing industrials.

Typical application: UV exposure of inks and varnishes responsive to 420Nm wavelength, most common industrials that we are supplying are:

Furniture & Woodworking, Marble & Granite, Plastic Packaging.

Metal Halide Lamp

Typical application: UV curing of inks and varnishes responsive to 365Nm wavelength.

The medium-pressure metal halide ultraviolet lamp is composed of a quartz envelope containing mercury and metal halide pellets additives, which create ultraviolet light of a specific wavelength. The wavelength of the added metal halide will be strongly transferred to the visible light spectrum output, resulting in a longer wavelength for deeper curing process.

Metal halide lamps are widely used in the printing industry and various industrial applications, such as LCD, CD / DVD production, printed circuit boards, wood industry, etc.

TSTUV manufacture replication lamps for most existing medium-pressure UV lamps from 800 watts on the market.

Exposure Lamp for PCB Market

Typical spectrum output of Exposure doped lamp

Typical application:

UV exposure of inks and varnishes responsive to 374Nm wavelength,

The specific quality of the metal halide lamp can extend the service life of the lamp tube through a shorter exposure time.

The medium-pressure metal halide ultraviolet lamp is composed of a quartz envelope containing mercury and metal halide pellets additives, which create ultraviolet light of a specific wavelength. The wavelength of the added metal halide will be strongly transferred to the visible light spectrum output, resulting in a wider wavelength for deeper curing process. We supply various of this kind of UV lamp for the market of Printing circuit board from lamp power 3KW to 12KW.

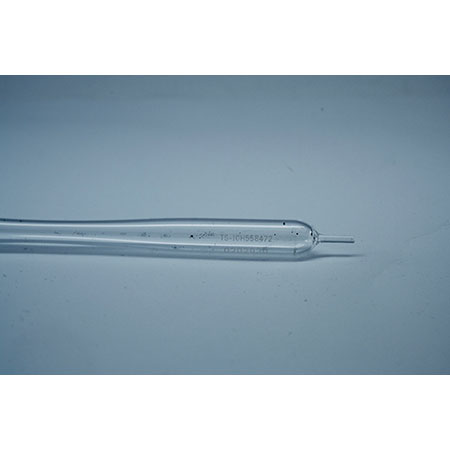

UV Capillary Lamp

Typical spectrum output of mercury lamp

Typical application: UV curing of inks and varnishes responsive to 365Nm wavelength.

Feature/Application

Mercury capillary lamps provide an intense source of radiant energy from the ultraviolet through the near infrared range. These lamps require no warming-up period for starting or restarting and reach near full brightness within seconds. They come in a variety of arc length, radiant power, and mounting methods, and are used in industrial settings (i.e., for printed circuit boards).

Optional reflective coating to shorten ignition warm up time

Optional lamp base – ceramic & metal base with or without power cable along with different terminals.

Arc length from 80mm up to 2000mm

Outer diameter from 10mm up to 40mm

Power density from 40W/cm up to 300W/cm

APPLICATIONS

UV Curing of Solvent-Free Paints, Coatings, and Adhesives

Industrial Photochemistry

Special Applications Such as Ozone Production and UV Analysis

UV Curing Lamp & Lamp Bases

Typical spectrum output of mercury lamp

Typical application: UV curing of inks and varnishes responsive to 365Nm wavelength.

Medium Pressure Mercury-Arc lamp

TYNGSHUOH TECH produces standard and custom UV Curing Lamps. Our production facility is designed to meet specific customer requirements to produce customized UV lamps, as well as achieve consistent quality in mass production. We design our own production machines with PLC program controller, we are able to optimize our manufacturing process. This results in precision filling technology making our lamps virtually free of impurities, thus preventing early blackening of the lamp. These lamps are components which may be used by customers to manufacture a variety of finished products.

BENEFITS

Consistent quality for small or large quantity production

Precise filling technology

Optional reflective coating to shorten ignition warm up time

Optional lamp base – ceramic & metal base with or without power cable along with different terminals.

Arc length from 80mm up to 2000mm

Outer diameter from 10mm up to 40mm

Power density from 40W/cm up to 300W/cm

APPLICATIONS

UV Curing of Solvent-Free Paints, Coatings, and Adhesives

Industrial Photochemistry

Special Applications Such as Ozone Production and UV Analysis

Electrodeless UV Lamp

Electrodeless bulbs, more commonly known as microwave lamps, are an extraordinary type of medium pressure mercury vapor lamp. The design concept is the mercury contained in the quartz sleeve is vaporized by irradiating the lamp with microwave energy (magnetron generator) rather than passing current between the electrodes. This offers few distinct advantages over the conventual electrode UV lamp:

Instant on/off capability

Smaller lamp design

Much longer lamp life (3~5 times a conventual electrode UV lamp)

More efficiency light output

Stronger intensity light at working surface

TSTUV supply microwave bulbs available in 6” (152.4 mm) and 10” (254 mm) lengths with power ratings of 300 & 600 WPI (watts per inch) which are made in the USA and are directly interchangeable with the electrodeless lamps made by OEM’s UV Systems Inc.

Metal Halide doping is used to change the spectral output of these lamps.

6” H type Electrodeless UV Lamp

The “H” bulb is a medium pressure Mercury vapor bulb that produces a conventional Mercury spectral output, which includes light wavelengths distributed across the entire UV range. H bulbs are typically used in applications that cure efficiently with high intensity light in the UVC and UVA ranges.

10” H⁺ type Electrodeless UV Lamp

The “H⁺” bulb is a medium pressure Mercury vapor bulb that produces a range of light output from a conventional Mercury spectrum, which includes light wavelengths distributed across the entire UV range. The H+ bulb is very similar to the H bulb, except the H+ bulb produces about 10% more light in the UVC range, which is effective in achieving good surface cure properties.

D type Electrodeless UV Lamp

The “D” bulb is a medium pressure Mercury vapor bulb with a unique metal additive. When energized, the metal additive and Mercury vaporize into a plasma to produce a wide distribution range of UV light with most of its output in the UVA range. In fact, the output of the D bulb is about 2-3 times higher in the UVA range compared to the H bulb, which makes this bulb extremely effective when curing through heavily pigmented resins or thick layers of clear resins.

V type Electrodeless UV Lamp

The “V” bulb is a medium pressure Mercury vapor bulb with a unique metal additive. When energized, the metal additive and Mercury vaporize into a plasma to produce a wide distribution range of UV light with most of its output in the UV-V range. The UV-V wavelength range is extremely effective when curing through the depths of pigmented resins, and particularly effective when curing white pigmented resins.

Selecting the right UV long arc curing lamp involves considering several factors:

Wavelength: Match the lamp’s output with the photo-initiators in your material.

Intensity: Ensure the lamp provides sufficient UV light to achieve thorough curing.

Size and Configuration: Choose a lamp that fits the spatial configuration of your machinery and the scale of your production.

Recent advancements in UV technology have led to the development of more efficient and environmentally friendly UV Lamps. These innovations are expected to drive their adoption across more industries, promising lower operating costs and reduced environmental impact.

The production of

Wavelength: Match the lamp’s output with the photo-initiators in your material.

Intensity: Ensure the lamp provides sufficient UV light to achieve thorough curing.

Size and Configuration: Choose a lamp that fits the spatial configuration of your machinery and the scale of your production.

Recent advancements in UV technology have led to the development of more efficient and environmentally friendly UV Lamps. These innovations are expected to drive their adoption across more industries, promising lower operating costs and reduced environmental impact.

The production of

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文