Fusion UV Lamp are advanced ultraviolet light sources commonly used in the process of curing inks, coatings, and adhesives. These lamps utilize a technology that allows for rapid curing, which is essential for high-speed production environments.

The versatility of UV Lamp enables their use across a variety of industries. Key applications include printing, where they help in setting inks on paper and plastics; electronics manufacturing, for curing adhesives and conformal coatings; and the automotive sector, where they cure coatings on parts and assemblies.

The versatility of UV Lamp enables their use across a variety of industries. Key applications include printing, where they help in setting inks on paper and plastics; electronics manufacturing, for curing adhesives and conformal coatings; and the automotive sector, where they cure coatings on parts and assemblies.

Fusion UV Lamp

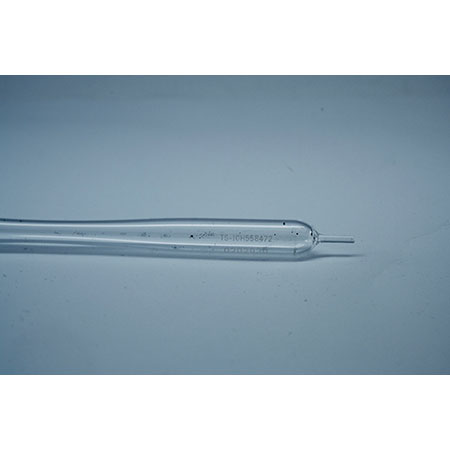

Electrodeless UV Lamp

Electrodeless bulbs, more commonly known as microwave lamps, are an extraordinary type of medium pressure mercury vapor lamp. The design concept is the mercury contained in the quartz sleeve is vaporized by irradiating the lamp with microwave energy (magnetron generator) rather than passing current between the electrodes. This offers few distinct advantages over the conventual electrode UV lamp:

Instant on/off capability

Smaller lamp design

Much longer lamp life (3~5 times a conventual electrode UV lamp)

More efficiency light output

Stronger intensity light at working surface

TSTUV supply microwave bulbs available in 6” (152.4 mm) and 10” (254 mm) lengths with power ratings of 300 & 600 WPI (watts per inch) which are made in the USA and are directly interchangeable with the electrodeless lamps made by OEM’s UV Systems Inc.

Metal Halide doping is used to change the spectral output of these lamps.

6” H type Electrodeless UV Lamp

The “H” bulb is a medium pressure Mercury vapor bulb that produces a conventional Mercury spectral output, which includes light wavelengths distributed across the entire UV range. H bulbs are typically used in applications that cure efficiently with high intensity light in the UVC and UVA ranges.

10” H⁺ type Electrodeless UV Lamp

The “H⁺” bulb is a medium pressure Mercury vapor bulb that produces a range of light output from a conventional Mercury spectrum, which includes light wavelengths distributed across the entire UV range. The H+ bulb is very similar to the H bulb, except the H+ bulb produces about 10% more light in the UVC range, which is effective in achieving good surface cure properties.

D type Electrodeless UV Lamp

The “D” bulb is a medium pressure Mercury vapor bulb with a unique metal additive. When energized, the metal additive and Mercury vaporize into a plasma to produce a wide distribution range of UV light with most of its output in the UVA range. In fact, the output of the D bulb is about 2-3 times higher in the UVA range compared to the H bulb, which makes this bulb extremely effective when curing through heavily pigmented resins or thick layers of clear resins.

V type Electrodeless UV Lamp

The “V” bulb is a medium pressure Mercury vapor bulb with a unique metal additive. When energized, the metal additive and Mercury vaporize into a plasma to produce a wide distribution range of UV light with most of its output in the UV-V range. The UV-V wavelength range is extremely effective when curing through the depths of pigmented resins, and particularly effective when curing white pigmented resins.

Selecting the ideal

Wavelength: Different curing processes require specific UV wavelengths. Ensure the lamp’s output matches your material requirements.

Intensity: The intensity of the lamp affects curing speed and quality. High-intensity lamps can reduce curing times significantly.

Size and Compatibility: The lamp should fit within your existing equipment setup without requiring extensive modifications.

Q: How long do typically last?

A: The lifespan of a can vary, but generally, they last for several thousand hours with proper maintenance.

Q: What maintenance is required for UV Lamp?

A: Regular cleaning of the lamp and reflectors, along with periodic replacement of the lamp and filters, is essential for optimal performance.

The UV Lamp market is witnessing significant growth driven by the demand for environmentally friendly curing solutions. Innovations in lamp technology are making them more energy-efficient and capable of delivering higher intensities with lower heat output.

The production of

Essential for industries that require fast and effective curing. With continuous technological advancements, these lamps are becoming more efficient and tailored to specific industrial needs, ensuring they remain a top choice for worldwide.

Fusion UV Lamp

involves understanding several critical factors:Wavelength: Different curing processes require specific UV wavelengths. Ensure the lamp’s output matches your material requirements.

Intensity: The intensity of the lamp affects curing speed and quality. High-intensity lamps can reduce curing times significantly.

Size and Compatibility: The lamp should fit within your existing equipment setup without requiring extensive modifications.

Q: How long do typically last?

A: The lifespan of a can vary, but generally, they last for several thousand hours with proper maintenance.

Q: What maintenance is required for UV Lamp?

A: Regular cleaning of the lamp and reflectors, along with periodic replacement of the lamp and filters, is essential for optimal performance.

The UV Lamp market is witnessing significant growth driven by the demand for environmentally friendly curing solutions. Innovations in lamp technology are making them more energy-efficient and capable of delivering higher intensities with lower heat output.

The production of

Fusion UV Lamp

involves sophisticated technology to ensure they deliver consistent UV light. High-quality manufacturers and suppliers invest in research and development to enhance lamp life and performance, using premium materials and rigorous testing protocols.Essential for industries that require fast and effective curing. With continuous technological advancements, these lamps are becoming more efficient and tailored to specific industrial needs, ensuring they remain a top choice for worldwide.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文