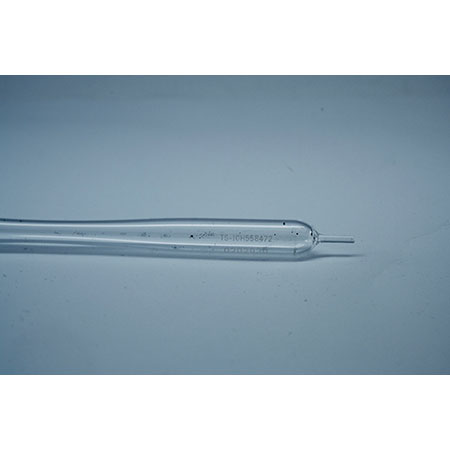

Electrodeless UV Lamp

We are at the forefront of developing Electrodeless UV Lamp technologies that are transforming industries from water purification to air sterilization. Our commitment is to provide cutting-edge solutions that offer superior performance, longevity, and environmental sustainability. Leverage magnetic induction instead of traditional electrodes, leading to a dramatic increase in lamp life and efficiency. This technology eliminates the common failure points associated with electrode wear and tear, thereby enhancing reliability and reducing maintenance costs. The lamps are designed to provide consistent UV output over an extended period, ensuring optimal disinfection and treatment processes without the need for frequent replacements.

Electrodeless UV Lamp

Model - TS-6H, TS-6D, TS-10H, TS-10D

Electrodeless UV Lamp

Electrodeless bulbs, more commonly known as microwave lamps, are an extraordinary type of medium pressure mercury vapor lamp. The design concept is the mercury contained in the quartz sleeve is vaporized by irradiating the lamp with microwave energy (magnetron generator) rather than passing current between the electrodes. This offers few distinct advantages over the conventual electrode UV lamp:

TSTUV supply microwave bulbs available in 6” (152.4 mm) and 10” (254 mm) lengths with power ratings of 300 & 600 WPI (watts per inch) which are made in the USA and are directly interchangeable with the electrodeless lamps made by OEM’s UV Systems Inc.

Metal Halide doping is used to change the spectral output of these lamps.

Electrodeless bulbs, more commonly known as microwave lamps, are an extraordinary type of medium pressure mercury vapor lamp. The design concept is the mercury contained in the quartz sleeve is vaporized by irradiating the lamp with microwave energy (magnetron generator) rather than passing current between the electrodes. This offers few distinct advantages over the conventual electrode UV lamp:

- Instant on/off capability

- Smaller lamp design

- Much longer lamp life (3~5 times a conventual electrode UV lamp)

- More efficiency light output

- Stronger intensity light at working surface

TSTUV supply microwave bulbs available in 6” (152.4 mm) and 10” (254 mm) lengths with power ratings of 300 & 600 WPI (watts per inch) which are made in the USA and are directly interchangeable with the electrodeless lamps made by OEM’s UV Systems Inc.

Metal Halide doping is used to change the spectral output of these lamps.

Recognizing the diverse needs of our clients, we offer customizable

Our capabilities as global suppliers enable us to serve customers around the world, ensuring they have access to our advanced technology no matter their location. We provide comprehensive support throughout the product lifecycle, from design consultation and installation to after-sales service and technical support, ensuring our clients achieve the best results from their UV technology investments. The game-changer in the field of ultraviolet light applications. Our ongoing commitment to innovation, tailored solutions, and sustainability makes us a trusted partner in the industry. Choose our lamps for your UV needs and experience a new standard of efficiency and reliability.

Electrodeless UV Lamp

designs to fit a variety of systems and applications. Whether integrating into existing water treatment facilities or developing specialized systems for medical sterilization, our lamps can be tailored to meet specific requirements, ensuring maximum efficiency and compatibility. As a leading manufacturer, quality is at the core of everything we do. Each of ourElectrodeless UV Lamp

is produced under stringent quality control measures to ensure they meet international safety and performance standards. We are also dedicated to minimizing our environmental impact, utilizing green manufacturing practices and materials that are recyclable and energy-efficient.Our capabilities as global suppliers enable us to serve customers around the world, ensuring they have access to our advanced technology no matter their location. We provide comprehensive support throughout the product lifecycle, from design consultation and installation to after-sales service and technical support, ensuring our clients achieve the best results from their UV technology investments. The game-changer in the field of ultraviolet light applications. Our ongoing commitment to innovation, tailored solutions, and sustainability makes us a trusted partner in the industry. Choose our lamps for your UV needs and experience a new standard of efficiency and reliability.

Enquiry Now

Products List

6” H type Electrodeless UV Lamp

The “H” bulb is a medium pressure Mercury vapor bulb that produces a conventional Mercury spectral output, which includes light wavelengths distributed across the entire UV range. H bulbs are typically used in applications that cure efficiently with high intensity light in the UVC and UVA ranges.

10” H⁺ type Electrodeless UV Lamp

The “H⁺” bulb is a medium pressure Mercury vapor bulb that produces a range of light output from a conventional Mercury spectrum, which includes light wavelengths distributed across the entire UV range. The H+ bulb is very similar to the H bulb, except the H+ bulb produces about 10% more light in the UVC range, which is effective in achieving good surface cure properties.

D type Electrodeless UV Lamp

The “D” bulb is a medium pressure Mercury vapor bulb with a unique metal additive. When energized, the metal additive and Mercury vaporize into a plasma to produce a wide distribution range of UV light with most of its output in the UVA range. In fact, the output of the D bulb is about 2-3 times higher in the UVA range compared to the H bulb, which makes this bulb extremely effective when curing through heavily pigmented resins or thick layers of clear resins.

V type Electrodeless UV Lamp

The “V” bulb is a medium pressure Mercury vapor bulb with a unique metal additive. When energized, the metal additive and Mercury vaporize into a plasma to produce a wide distribution range of UV light with most of its output in the UV-V range. The UV-V wavelength range is extremely effective when curing through the depths of pigmented resins, and particularly effective when curing white pigmented resins.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文