Teflon Fabrics, known for their exceptional non-stick and high-temperature resistance properties, are engineered textiles that serve a variety of applications across multiple industries. These fabrics are coated with polytetrafluoroethylene (PTFE), giving them their unique characteristics.

... are extensively used in sectors such as aerospace, food processing, and construction. They are ideal for applications requiring high chemical resistance, thermal stability, and low friction. Common uses include conveyor belts, protective clothing, and insulation materials.

... are extensively used in sectors such as aerospace, food processing, and construction. They are ideal for applications requiring high chemical resistance, thermal stability, and low friction. Common uses include conveyor belts, protective clothing, and insulation materials.

Teflon Fabrics

PTFE coated Glass Fabric for Conveyor Belting

Most belts are made from electrical, premium or standard grade fabrics, especially where fabric weave impression is undesirable or where sticky or gummy materials are being conveyed. Industrial and mechanical grade PTFE coated conveyor belts are preferred where economy is more important than maximum resistance to chemicals or solvents. Crease and tear resistant PTFE coated conveyor belts are suggested for higher speeds such as for packaging belts.

Closed weave porous belts and open mesh PTFE belts are specified for applications where porosity is required as in drying applications (e.g. textile dryer belts) or microwave cooking ovens. Our anti-static range is used where static build up may occur such as in fuse press applications.

Screen Printing PTFE coated glass fabrics

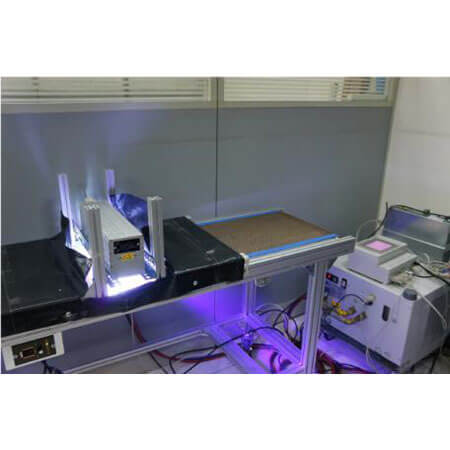

GCTC is the market leader in Teflon conveyor belts, which are suitable for use in various ovens and curing equipment. Our company uses the professional equipment built by our own engineering team to custom design and produce all our belts.

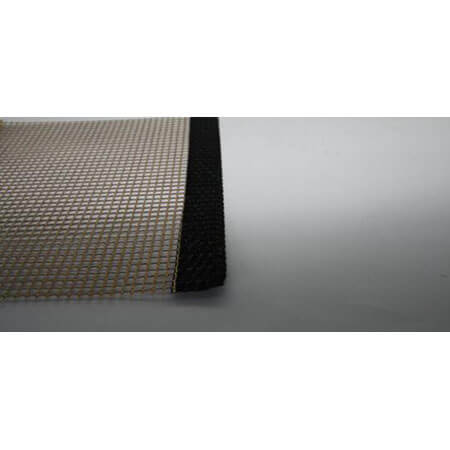

The main material type used in these styles of conveyor belts is PTFE-coated open mesh. The mesh size ranges from 1mm to 5mm openings, of which 4mm is our most common. We can specify the standard brown or antistatic black type, depending on the type of dryer they are installed.

We produce belts with a maximum width of 5000mm in a mesh size of 4mm, which allows us to provide belts for most machine width conveyors on the market today.

We have installed many types of fasteners for conveyor-specific belts, including helical metal and soft materials, as well as Kevlar shaped bull nose rings. Both designs can achieve a strong joint and have maximum airflow, thereby maximizing the dryness of the entire belt surface.

Our Teflon conveyor belt can run in an environment of 260 ° C, and can use UV, IR and hot-air drying methods as the heat source.

We can provide a variety of different belt guide anti-overflow practice options, which can be installed on the edge of the belt to help constant belt positioning in the dryer. These anti-pass devices and practices are related to cost and usage, and can be specified in the design stage.

Textile Garment Manufacture

PTFE Coated Glass Fabrics for use in Textile Manufacturing

Our PTFE coated fabrics have the following uses in textile production:

Conveyor belts for high temperature processing of natural and synthetic, knitted, *woven and non-woven textiles *Thermal bonding *Covers for drying cylinders

Lamination to foam and other polymeric sheeting *Cutting table covers

Apparel Fusion Machines

The main features are:

Non-stick

Ant-Static

Heat resistant

Smooth surface

Easily cleaned

Heat dissipation

(e.g. textile dryer belts) or microwave cooking ovens. Our anti-static range is used where static build up may occur such as in fuse press applications.

Food & Beverage

Food Quality PTFE coated glass & aramid fabrics

Our PTFE coated fabrics are used in the following food processes:

Contact cooking

Cooling & freezing

Baking

Sterilizing

Drying, including vacuum drying

Sizing

Lining chutes

Vessel linings

Conveyor belting

They are suitable for use by the consumer as baking sheets, chip baskets, oven liners and BBQ,covers, among many other applications.

Features & benefits:

Non-stick

Non-toxic

Inert

Coatings comply with FDA and USDA regulations

Unaffected by microwaves

Easy clean

-150°C to +260°C range (please specify end use)

Electronics

Electronics PTFE coated glass and Kevlar fabrics

Our PTFE coated fabrics are used in the following Electronics processes:

Semi-conductor production

Capacitor and battery cell manufacture

Capacitor and battery cell manufacture

Wire and cable insulation

LCD & LED screen manufacturing

Telecommunications manufacture

PCB BGA Seal Circuit Board cleaning machine

Features & benefits:

Non-stick

Low friction

Microwaveable

Inert

Anti-static

Lightweight

Flexible

High tensile strength

Joining methods for Teflon Conveyor belts & power transmission belts

The fabric ends are cut in a finger pattern, matched together, then hot pressed. With this kind of joint, the weld length is decisive for the tensile strength. The joint part is quite flat, and it has a good result in the transporting article that require a flat joint. Application industries including apparel fusion machines, food conveyors (ex. egg crust, Mexican crust pre-cooking automation equipment), electronic parts, etc.

Joining methods for Teflon Conveyor belts & power transmission belts

The ends of the fabric are skived to a wedge shape, one end of the belt from the top, the other from the underside, and bonded together using PFA film, heat and pressure. This is a very strong welding method, and offer a very smooth transition for the product to run on the machine.

Joining methods for Teflon Conveyor belts & power transmission belts

Mechanical fasteners join or fasten two objects together mechanically. They are used in places where conveyor belts must be changed regularly or for applications where the belt needs to be replaced quickly. However, the mechanical fastener is a vulnerable part of the belt and may have openings where dirt can enter, so this is not a preferred solution for many applications.

Joining methods for Teflon Conveyor belts & power transmission belts

Butt joint is made by placing the two ends of a belt together and applying a certain wide piece of material underneath. This is then welded together ensuring the top surface is neat. Butt Belt Joints tend to be manufactured prior to fitting on the machine and are manufactured using a strap on the underside to offer additional strength. This method is a simple but very effective on making a belt endless at customer’s site. In the meantime, it can be an idea for machine isn’t easy to unassembled for belt replacement.

Joining methods for Teflon Conveyor belts & power transmission belts

With pre-inserted staples and a one-piece strip design, which Hinged and Stapled Fasteners makes splicing quick and easy (allows for quicker installation and easy change). The joint portion is flexible and it is made with special plastic material which allows you to use it in a certain high temperature environment, please contact us for more details.

Joining methods for Teflon Conveyor belts & power transmission belts

A castellated joint is made by creating interlocking loops from PTFE coated Kevlar materials. The two ends can then be connected together with a metal or peek pin. This method is easy to install on the machine while it has a feature of more flat than spiral peek joint method.

Joining methods for Teflon Conveyor belts & power transmission belts

Overlap Belt Joints – Overlap joints are a simple and easy joint to use where having an even surface is not critical. Overlap splices are the most popular type used in the industry and can be enhanced with molding for food processing applications. Overlap ranges from 25 mm to 140mm, with directional belt angles of 30, 45, 60, and 90 degrees. This type of joint can easy be made on a machine where the belt needs to be fitted onsite.

Joining methods for Teflon Conveyor belts & power transmission belts

We recommend the overlapped finger joint. As in this case, the ends to be joined are split into layers. Next, fingers are punched into the ends, which are then tacked together and welded under pressure and heat into an endless belt.

Again, the double-layer fabric is applied from the beginning to the end, using high temperature and pressure, so the tensile strength of the belt will be improved and it is especially suitable for conveyors with small wheel diameters, such as continuous sealing machinery and toilet paper packaging machinery.

Edging reinforcement and Tracking types

GCTC provide most of kinds of processing solutions to strengthen the edge of the conveyor belt, mainly to provide the anti-resistance feature and service life time of the belt. The most common way is to use a Teflon film to cover the edge for 1- inch width, and then place under the laminating machine with high temperature and pressure to cover the edge perfectly. Alternative way is using a piece of glass Fiber fabrics sewing onto the edges. To prevent direction shift t you can choose Kevlar or silicone rope to form the guide rope and sew it at a distance of 1/2" from the edge. This is a customized option. The following pictures and abbreviations are available for your reference.

Edge reinforcement - Teflon Glass Fabric Edging

Tracking Kevlar Rope

Silicone Tracking Rope

Tracking Eyelet

Heat Sealing PTFE coated fabric paper packaging belt

Our PTFE(Teflon)coated fabrics have the following uses in heat sealing applications:

Side sealer belts for polythene(PE)packaging

Mesh belts for heat shrink tunnels

Release fabrics for uPVC welding platens

Non-stick fabrics for covering hot wire sealing processes

Features & Benefits:

Low friction

Non-stick

High temperature resistance

Heat transfer

High tensile strength Flexible

PTFE (Teflon) Fabric Belt processing related materials

GLORYCITY supply portable heat sealers specially designed to seal PTFE (Teflon) coated glass fabrics as belts with temperature controller (temperature up to 500℃),it is portable design which is especially convenience for working the site of customer. These heat sealers are customized set, please specify your need of dimensions of width in order to obtain the most suitable heat sealer.

PTFE (Teflon) Fabric Belt processing related materials

We also provide the associated materials for PTFE (Teflon) coated glass belt processing; such as heat bonding PFA or FEP films, insulating boards, Kapton film. With our specialized equipment and processes, we can provide tight tolerances and fast setup services to meet your needs. We can fill large quantity orders as well as small prototype runs—and can do so with quick, two- to three-day turn arounds. Please specify the dimensions on ordering.

PTFE (Teflon) Fabric Belt processing related materials

We also provide the associated materials for PTFE (Teflon) coated glass belt processing; such as Kevlar sewing yarns and tracking ropes in variety dimensions; Kevlar tracking rope is a brilliant idea to get straight and smooth belt running conditions, Please specify the dimensions on ordering, we always keep the most common using dimensions as 3.5mm, 4.0mm & 5.0mm on stocks.

PTFE Coated Glass Fabric Adhesive Tape

PTFE coated glass with pressure sensitive silicone adhesive applied to one side, available with a release liner or as self-wound, supplied between 5mm and 1010mm wide.

Woven glass fabric coated with PTFE (polytetrafluoroethylene) and silicone pressure sensitive adhesive which provides an excellent release surface for a diversity of industrial applications requiring high temperature, electrical resistance, mechanical strength, fire retardancy and cost effectiveness.

These tapes are produced with silicone pressure sensitive adhesive which have a continuous operating temperature range between -72 ℃to +260℃.

These tapes are frequently used in Heat Sealing applications with the packaging industries:

Side Sealers

Impulse Sealers

Blister Packs

Fill & Form Sealers

L Bar Sealers

The most popular items which we keep in our warehouse in case to provide the fastest delivery.

Non-stick, one side adhesive, PTFE coated glass fabric

Technical Data Sheet

Typical Properties

Nominal Values

Test method

Coated fabric Thickness (mm)

0.076

Coated Fabric Weight (g/m²)

130

% PTFE coated

63

Adhesive Weight (g/m²)

55

Warp Tensile Strength (N/5cm)

1000

RS3424 : Part 4

Warp Tongue Tear Strength (N)

15

RS3424: Part 5

Coating Adhesive (N/5cm)

N/A

RS3424 : Part 7

Peel Adhesion (N/2.5cm)

12

BS ENISO 28510:1993

Surface Resistance ( /m²)

Insulative

Operating Temperature (℃)

-72 ~ +260

Non-stick, one side adhesive, coated glass fabric

Technical Data Sheet

Typical Properties

Nominal Values

Test method

Coated fabric Thickness (mm)

0.08

Coated Fabric Weight (g/m²)

150

Adhesive Weight (g/m²)

55

Warp Tensile Strength (N/5cm)

1000

RS3424 : Part 4

Warp Tongue Tear Strength (N)

15

RS3424: Part 5

Coating Adhesive (N/5cm)

N/A

RS3424 : Part 7

Peel Adhesion (N/2.5cm)

12

BS ENISO 28510:1993

Surface Resistance ( /m²)

Insulative

Operating Temperature (℃)

-72 ~ +260

Non-stick, one side adhesive, coated glass fabric

Technical Data Sheet

Typical Properties

Nominal Values

Test method

Coated fabric Thickness (mm)

0.142

Coated Fabric Weight (g/m²)

290

% PTFE coated

64

Adhesive Weight (g/m²)

55

Warp Tensile Strength (N/5cm)

1600

RS3424 : Part 4

Warp Tongue Tear Strength (N)

23

RS3424: Part 5

Coating Adhesive (N/5cm)

N/A

RS3424 : Part 7

Peel Adhesion (N/2.5cm)

12

BS ENISO 28510:1993

Surface Resistance ( /m²)

Insulative

Operating Temperature (℃)

-72 ~ +260

Non-stick, tear resist, coated glass fabric

Technical Data Sheet

Typical Properties

Nominal Values

Test method

Coated fabric Thickness (mm)

0.076

Coated Fabric Weight (g/m²)

126

% PTFE coated

60

Adhesive Weight (g/m²)

260

Warp Tensile Strength (N/5cm)

1600

RS3424 : Part 4

Warp Tongue Tear Strength (N)

50

RS3424: Part 5

Coating Adhesive (N/5cm)

N/A

RS3424 : Part 7

Surface Resistance ( /m²)

Insulative

Operating Temperature (℃)

-72 ~ +260

PTFE coated glass Fabrics

PTFE coated glass and aramid fabrics that offer a wide range of useful physical properties, no other plastics material can match tis combination of properties.

High temperature resistance (-70℃~+260℃)

Low friction

Outstanding dielectric strength

Excellent chemical resistance

Inherent strength & flexibility

Non-toxic

Non-stick

Excellent release

Resistance to UV and HF

Silicone rubber coated glass fabric

GCTC supply silicone coated fabrics exhibit very similar properties to PTFE fluorocarbon resin and PTFE coated fabrics:

Excellent Release properties up to 230°C

Silicone coated surfaces exhibit excellent release characteristics and will release adhesive and viscous materials which often adhere to a PTFE fluorocarbon resin.

Good Chemical Resistance

Silicone coated fabrics exhibit high resistance to attack from mild alkali, non-oxidizing acids, most salts, mineral lubricating oil, air, moisture and sunlight.

Superior Abrasion Resistance and Flex

Silicone coated fabrics offer a tough coated surface with high abrasion and flex resistance. Silicone coated fabrics, however do not exhibit the low friction surfaces or self- lubricating properties of fluorocarbon resins.

Super Dielectric Properties

Silicone coated fabrics are excellent electrical insulators in tough environments.

Food Grade PTFE coated glass fabric

Food grade, new development Non-stick PTFE coated, closed weave glass fabric is specially design for food cooking industry as delivering innovative customer solutions is our goal. Our food grade fabric is delivering with core characteristics:

High release non- stick surface

Temperature resistance (-73C to +260C)

Outstanding chemical resistance

Excellent fire resistance

Superior electrical properties

Water repellent & anti-staining coatings

Food approved coatings

PTFE coated glass baking fabric

Baking Sheets & Food Preparation

GCTC offers a material suitable for baking sheets for domestic or industrial purposes.

The baking sheet has been designed with the domestic/consumer market in mind. With its ultra-smooth, non-stick surface, even the stickiest foods are sure to lift clean away. These sheets are long-lasting and can be used in the hottest oven or microwave, up to 260°C. The special PTFE coated surface ensures the baking sheet can be used over and over again. Our products can be used for food preparation, lining cake tins, roasting tins, grill pans, baking trays, and even frying pans.

Depending on your preference, products include GC076G (76 microns) and GC013G (127 microns).

Our baking fabric is ideal for cooking buns, cakes, meringues, sticky pastries, biscuits, pizzas and oven chips.

To use any of our baking fabric just simply cut the sheet to the right size and position directly on the baking tray or pan. Then simply place the food on the sheet and cook as usual. After use, wipe clean or wash in warm soapy water. Store flat or rolled, please do not crease.

No pre-greasing or flouring necessary

Simply cut to size with a knife

Environmentally friendly

Easy wipe/wash clean

Dishwasher safe

Fat free cooking

Long lasting

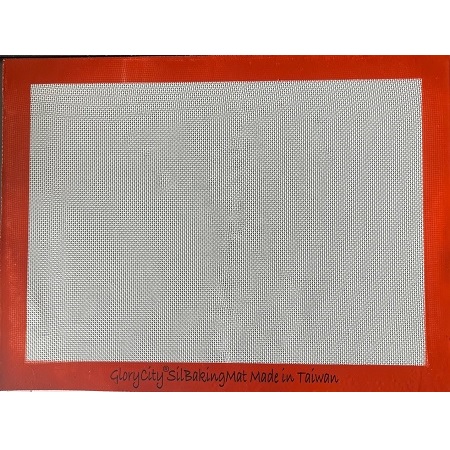

SILICONE BAKING MAT – A must-have kitchen baking accessories for any baker, these silicone baking mats are made with high strength glass fiber grid fabric as substrate and coated with silicone resin as baking sheets provide even heat distribution for food that helps you cook foods more efficiently and get higher-quality baking like a pro.

HEALTHY, NON-STICK COOKING SURFACE – these silicone sheets for baking has premium silicone, and fiberglass design that provides consistent heat distribution and promotes even baking, withstanding temperatures from -40℃to +250 ℃

to make it easier to bake cookies, candies, meats, or even fruits and vegetables without relying on unhealthy flour, fats, oils, or sprays.

PROFESSIONAL RELIABLE QUALITY – Made of food-grade silicone, this silicone baking sheet can be used for baking foods, kneading or rolling dough, creating crispy pizza or French fries, and making healthier foods for you, your family, and your guests with long-lasting reliability.

WASHABLE AND REUSABLE – Our non-stick baking sheet for oven use can be wiped clean with soap water or placed in the top rack of the dishwasher, making it easier to clean and reuse for breakfast, lunch, or dinner recipes. Easily to replace the traditional baking paper and spend no time for cleaning baking trays, our silicone mat makes your nonstick baking easier!

100% SATISFACTION SERVICE – What we want to provide with you is the best silicone cooking sheet with trusted customer service. Any questions, please do not hesitate to contact us, we will make you 100% satisfaction. Meanwhile, we can also provide customized sizes, colors and logos.

Typical Properties

Nominal Values

Thickness (mm)

0.63

Weight (g/m²)

916

Appearance

Butter White Food Grade

Coating (%)

36

Warp Tensile Strength (N/cm)

N/A

Warp Tear Resistance (N/cm)

N/A

Silicone Adhesion (KN/m)

17

Surface Resistance @100V (Ω/Sq)

Insulative

Operating Temperature (℃)

-20to +230

Selecting the correct Teflon fabric depends on:

Temperature Resistance: Ensure the fabric can withstand the operating temperatures of your application.

Thickness and Weight: Depending on the application, the fabric's weight and thickness might affect performance.

Chemical Compatibility: Check that the fabric is resistant to the chemicals it will be exposed to.

Q: Are safe for food-related applications?

A: Yes, when properly certified, safe for food contact and widely used in food production environments.

Q: How durable are?

A: Designed for durability, but lifespan can vary based on exposure to elements and mechanical wear.

It's important to choose suppliers that adhere to strict quality standards and offer reliable customer support.

The manufacturing process of

With their unparalleled resistance to heat, chemicals, and wear,

Temperature Resistance: Ensure the fabric can withstand the operating temperatures of your application.

Thickness and Weight: Depending on the application, the fabric's weight and thickness might affect performance.

Chemical Compatibility: Check that the fabric is resistant to the chemicals it will be exposed to.

Q: Are safe for food-related applications?

A: Yes, when properly certified, safe for food contact and widely used in food production environments.

Q: How durable are?

A: Designed for durability, but lifespan can vary based on exposure to elements and mechanical wear.

It's important to choose suppliers that adhere to strict quality standards and offer reliable customer support.

The manufacturing process of

Teflon Fabrics

involves high-tech procedures to apply the PTFE coating evenly across the textile base. Manufacturers are continually refining these processes to improve efficiency and product performance.With their unparalleled resistance to heat, chemicals, and wear,

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文