Plastic Spiral Peek Fastener For Mesh Conveyor Belt

In the dynamic world of conveyor technology, our company stands out as a premier manufacturer and supplier of innovative solutions. We are proud to introduce the Plastic Spiral Peek Fastener For Mesh Conveyor Belt, a groundbreaking product designed to enhance the durability and functionality of industrial conveyor systems. Our made from PEEK (Polyether Ether Ketone), a high-performance thermoplastic renowned for its exceptional mechanical and chemical resistance properties. This material ensures that our fasteners provide superior durability and reliability under extreme environmental conditions, including high temperatures and aggressive chemical exposure. Ideal for food processing, pharmaceuticals, and chemical industries, these fasteners offer a robust solution for securing mesh conveyor belts effectively.

Plastic Spiral Peek Fastener For Mesh Conveyor Belt

Model - Spiral PEEK Fastener

Joining methods for Teflon Conveyor belts & power transmission belts

With pre-inserted staples and a one-piece strip design, which Hinged and Stapled Fasteners makes splicing quick and easy (allows for quicker installation and easy change). The joint portion is flexible and it is made with special plastic material which allows you to use it in a certain high temperature environment, please contact us for more details.

With pre-inserted staples and a one-piece strip design, which Hinged and Stapled Fasteners makes splicing quick and easy (allows for quicker installation and easy change). The joint portion is flexible and it is made with special plastic material which allows you to use it in a certain high temperature environment, please contact us for more details.

The spiral design of our fasteners allows for easy installation and secure attachment, minimizing downtime and maintenance costs. This design ensures a strong hold and uniform distribution of load across the belt, enhancing the belt's overall strength and lifespan. The non-metallic nature of the PEEK material also means that our fasteners are lighter and do not corrode, making them a cost-effective and long-lasting solution. Understanding that each industry has unique needs, we offer customized solutions for our Plastic Spiral Peek Fasteners. Available in various sizes and specifications, our fasteners can be tailored to meet the specific requirements of any mesh conveyor belt system. Our expert team works closely with clients to ensure compatibility and optimal performance, providing tailored advice and support from initial design to final implementation.

We ensure that our Plastic Spiral Peek Fasteners for Mesh Conveyor Belt are readily available wherever our clients are located. We support our products with comprehensive logistics and customer service, ensuring timely delivery and exceptional post-sales support. Our dedicated team of professionals is committed to assisting you throughout the lifecycle of your product, from troubleshooting to regular maintenance updates. Choose the

We ensure that our Plastic Spiral Peek Fasteners for Mesh Conveyor Belt are readily available wherever our clients are located. We support our products with comprehensive logistics and customer service, ensuring timely delivery and exceptional post-sales support. Our dedicated team of professionals is committed to assisting you throughout the lifecycle of your product, from troubleshooting to regular maintenance updates. Choose the

Plastic Spiral Peek Fastener For Mesh Conveyor Belt

for your operations and benefit from a product that combines cutting-edge material science with practical, innovative design. Our commitment to quality, innovation, and customer satisfaction ensures that you receive a fastening solution that not only meets but exceeds industry standards.Enquiry Now

Products List

Joining methods for Teflon Conveyor belts & power transmission belts

The fabric ends are cut in a finger pattern, matched together, then hot pressed. With this kind of joint, the weld length is decisive for the tensile strength. The joint part is quite flat, and it has a good result in the transporting article that require a flat joint. Application industries including apparel fusion machines, food conveyors (ex. egg crust, Mexican crust pre-cooking automation equipment), electronic parts, etc.

Joining methods for Teflon Conveyor belts & power transmission belts

The ends of the fabric are skived to a wedge shape, one end of the belt from the top, the other from the underside, and bonded together using PFA film, heat and pressure. This is a very strong welding method, and offer a very smooth transition for the product to run on the machine.

Joining methods for Teflon Conveyor belts & power transmission belts

Mechanical fasteners join or fasten two objects together mechanically. They are used in places where conveyor belts must be changed regularly or for applications where the belt needs to be replaced quickly. However, the mechanical fastener is a vulnerable part of the belt and may have openings where dirt can enter, so this is not a preferred solution for many applications.

Joining methods for Teflon Conveyor belts & power transmission belts

Butt joint is made by placing the two ends of a belt together and applying a certain wide piece of material underneath. This is then welded together ensuring the top surface is neat. Butt Belt Joints tend to be manufactured prior to fitting on the machine and are manufactured using a strap on the underside to offer additional strength. This method is a simple but very effective on making a belt endless at customer’s site. In the meantime, it can be an idea for machine isn’t easy to unassembled for belt replacement.

Joining methods for Teflon Conveyor belts & power transmission belts

A castellated joint is made by creating interlocking loops from PTFE coated Kevlar materials. The two ends can then be connected together with a metal or peek pin. This method is easy to install on the machine while it has a feature of more flat than spiral peek joint method.

Joining methods for Teflon Conveyor belts & power transmission belts

Overlap Belt Joints – Overlap joints are a simple and easy joint to use where having an even surface is not critical. Overlap splices are the most popular type used in the industry and can be enhanced with molding for food processing applications. Overlap ranges from 25 mm to 140mm, with directional belt angles of 30, 45, 60, and 90 degrees. This type of joint can easy be made on a machine where the belt needs to be fitted onsite.

Joining methods for Teflon Conveyor belts & power transmission belts

We recommend the overlapped finger joint. As in this case, the ends to be joined are split into layers. Next, fingers are punched into the ends, which are then tacked together and welded under pressure and heat into an endless belt.

Again, the double-layer fabric is applied from the beginning to the end, using high temperature and pressure, so the tensile strength of the belt will be improved and it is especially suitable for conveyors with small wheel diameters, such as continuous sealing machinery and toilet paper packaging machinery.

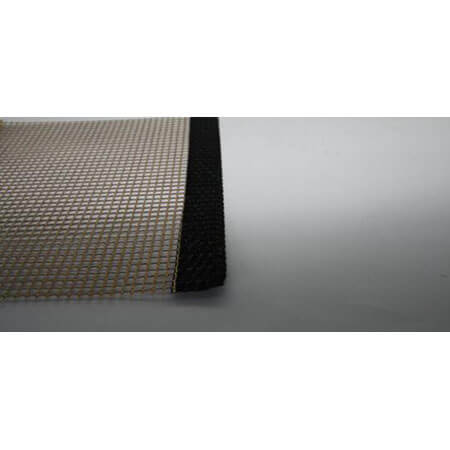

Edging reinforcement and Tracking types

GCTC provide most of kinds of processing solutions to strengthen the edge of the conveyor belt, mainly to provide the anti-resistance feature and service life time of the belt. The most common way is to use a Teflon film to cover the edge for 1- inch width, and then place under the laminating machine with high temperature and pressure to cover the edge perfectly. Alternative way is using a piece of glass Fiber fabrics sewing onto the edges. To prevent direction shift t you can choose Kevlar or silicone rope to form the guide rope and sew it at a distance of 1/2" from the edge. This is a customized option. The following pictures and abbreviations are available for your reference.

Edge reinforcement - Teflon Glass Fabric Edging

Tracking Kevlar Rope

Silicone Tracking Rope

Tracking Eyelet

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文