Teflon Conveyor Belt

As an industry-leading manufacturer and supplier, our company is proud to present our state-of-the-art Teflon Conveyor Belt solutions designed to revolutionize the handling processes across a variety of industries. Renowned for their durability and high performance, our Teflon belts meet the demanding conditions of modern production environments. Our products is crafted from high-quality Teflon, known for its exceptional resistance to heat, chemicals, and wear. This makes it ideally suited for applications ranging from food processing to the automotive industry, where reliability and hygiene are paramount. The non-stick surface of our belts ensures easy cleaning and maintenance, enhancing workflow efficiency and reducing downtime.

Teflon Conveyor Belt

Model - PTFE coated Fabric Conveyor Belts

PTFE coated Glass Fabric for Conveyor Belting

Most belts are made from electrical, premium or standard grade fabrics, especially where fabric weave impression is undesirable or where sticky or gummy materials are being conveyed. Industrial and mechanical grade PTFE coated conveyor belts are preferred where economy is more important than maximum resistance to chemicals or solvents. Crease and tear resistant PTFE coated conveyor belts are suggested for higher speeds such as for packaging belts.

Closed weave porous belts and open mesh PTFE belts are specified for applications where porosity is required as in drying applications (e.g. textile dryer belts) or microwave cooking ovens. Our anti-static range is used where static build up may occur such as in fuse press applications.

Most belts are made from electrical, premium or standard grade fabrics, especially where fabric weave impression is undesirable or where sticky or gummy materials are being conveyed. Industrial and mechanical grade PTFE coated conveyor belts are preferred where economy is more important than maximum resistance to chemicals or solvents. Crease and tear resistant PTFE coated conveyor belts are suggested for higher speeds such as for packaging belts.

Closed weave porous belts and open mesh PTFE belts are specified for applications where porosity is required as in drying applications (e.g. textile dryer belts) or microwave cooking ovens. Our anti-static range is used where static build up may occur such as in fuse press applications.

We understand that each industry has unique demands. That’s why we offer customizable

Our reach extends internationally, ensuring that our

Teflon Conveyor Belt

that can be tailored to various widths, lengths, and thicknesses to suit specific operational needs. Whether you require a belt for a small-scale bakery or a large-scale pharmaceutical plant, our expertise in Teflon technology allows us to provide a solution that integrates seamlessly into your existing setup. Each manufactured at our state-of-the-art facility where innovation meets craftsmanship. Employing advanced manufacturing techniques and rigorous quality control measures, we ensure that each conveyor belt not only meets but exceeds industry standards. Our commitment to quality and innovation is reflected in the longevity and performance of our products.Our reach extends internationally, ensuring that our

Teflon Conveyor Belt

are accessible to clients around the globe. We back our products with comprehensive support services, including professional consultation, installation guidance, and after-sales care. Our dedicated team of experts is committed to providing assistance that helps you achieve optimal performance and maximum return on investment. Choose our solutions for unmatched durability, efficiency, and customization options. With our advanced technology, commitment to quality, and comprehensive support, we empower your business to operate more effectively, meeting today's industrial challenges with tomorrow's technology.Enquiry Now

Products List

Screen Printing PTFE coated glass fabrics

GCTC is the market leader in Teflon conveyor belts, which are suitable for use in various ovens and curing equipment. Our company uses the professional equipment built by our own engineering team to custom design and produce all our belts.

The main material type used in these styles of conveyor belts is PTFE-coated open mesh. The mesh size ranges from 1mm to 5mm openings, of which 4mm is our most common. We can specify the standard brown or antistatic black type, depending on the type of dryer they are installed.

We produce belts with a maximum width of 5000mm in a mesh size of 4mm, which allows us to provide belts for most machine width conveyors on the market today.

We have installed many types of fasteners for conveyor-specific belts, including helical metal and soft materials, as well as Kevlar shaped bull nose rings. Both designs can achieve a strong joint and have maximum airflow, thereby maximizing the dryness of the entire belt surface.

Our Teflon conveyor belt can run in an environment of 260 ° C, and can use UV, IR and hot-air drying methods as the heat source.

We can provide a variety of different belt guide anti-overflow practice options, which can be installed on the edge of the belt to help constant belt positioning in the dryer. These anti-pass devices and practices are related to cost and usage, and can be specified in the design stage.

Textile Garment Manufacture

PTFE Coated Glass Fabrics for use in Textile Manufacturing

Our PTFE coated fabrics have the following uses in textile production:

Conveyor belts for high temperature processing of natural and synthetic, knitted, *woven and non-woven textiles *Thermal bonding *Covers for drying cylinders

Lamination to foam and other polymeric sheeting *Cutting table covers

Apparel Fusion Machines

The main features are:

Non-stick

Ant-Static

Heat resistant

Smooth surface

Easily cleaned

Heat dissipation

(e.g. textile dryer belts) or microwave cooking ovens. Our anti-static range is used where static build up may occur such as in fuse press applications.

Food & Beverage

Food Quality PTFE coated glass & aramid fabrics

Our PTFE coated fabrics are used in the following food processes:

Contact cooking

Cooling & freezing

Baking

Sterilizing

Drying, including vacuum drying

Sizing

Lining chutes

Vessel linings

Conveyor belting

They are suitable for use by the consumer as baking sheets, chip baskets, oven liners and BBQ,covers, among many other applications.

Features & benefits:

Non-stick

Non-toxic

Inert

Coatings comply with FDA and USDA regulations

Unaffected by microwaves

Easy clean

-150°C to +260°C range (please specify end use)

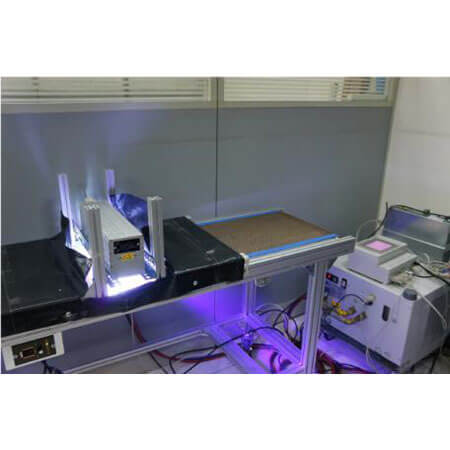

Electronics

Electronics PTFE coated glass and Kevlar fabrics

Our PTFE coated fabrics are used in the following Electronics processes:

Semi-conductor production

Capacitor and battery cell manufacture

Capacitor and battery cell manufacture

Wire and cable insulation

LCD & LED screen manufacturing

Telecommunications manufacture

PCB BGA Seal Circuit Board cleaning machine

Features & benefits:

Non-stick

Low friction

Microwaveable

Inert

Anti-static

Lightweight

Flexible

High tensile strength

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文