UV Capillary Exposure Lamp

We specialize in the design and production of UV Capillary Exposure Lamp systems, which are crucial for high-precision photolithography in the electronics and printing industries. We are committed to providing solutions that enhance the accuracy and efficiency of capillary film exposure. Our Engineered to deliver a uniform and intense UV light, ensuring precise exposure that is essential for fine feature reproduction on capillary films. The technology behind our lamps focuses on maximizing light distribution accuracy and minimizing exposure time, which is vital for achieving high-resolution results in sensitive photolithographic processes.

UV Capillary Exposure Lamp

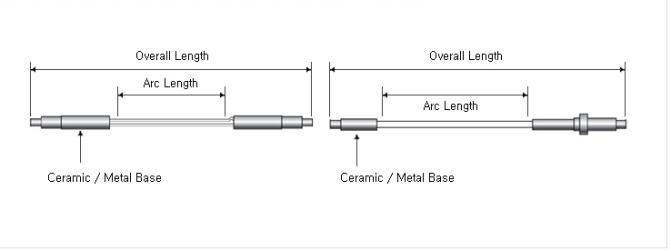

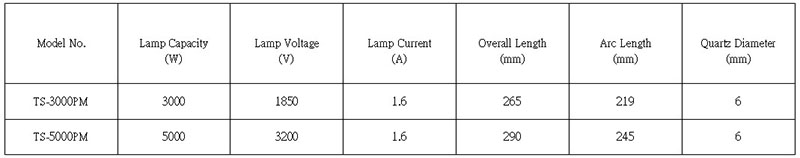

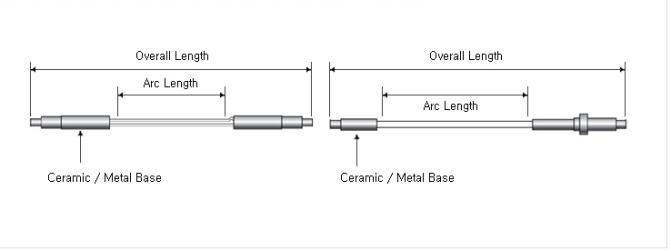

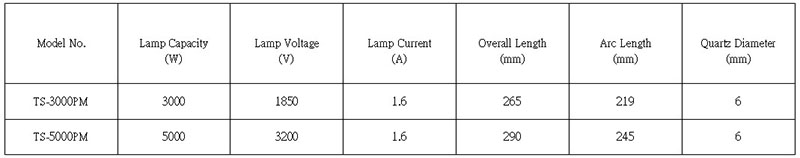

Model - TS-3000PM/TS-5000PM

UV Capillary Lamp

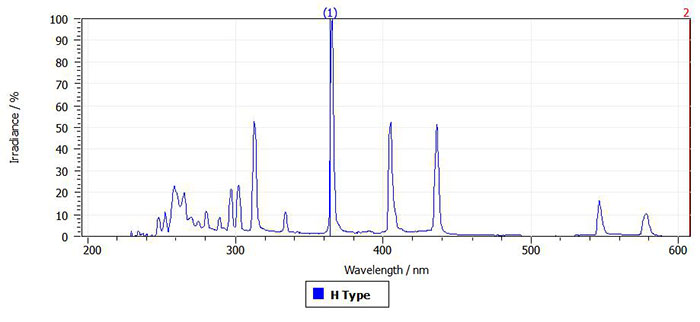

Typical spectrum output of mercury lamp

Typical application: UV curing of inks and varnishes responsive to 365Nm wavelength.

Feature/Application

Mercury capillary lamps provide an intense source of radiant energy from the ultraviolet through the near infrared range. These lamps require no warming-up period for starting or restarting and reach near full brightness within seconds. They come in a variety of arc length, radiant power, and mounting methods, and are used in industrial settings (i.e., for printed circuit boards).

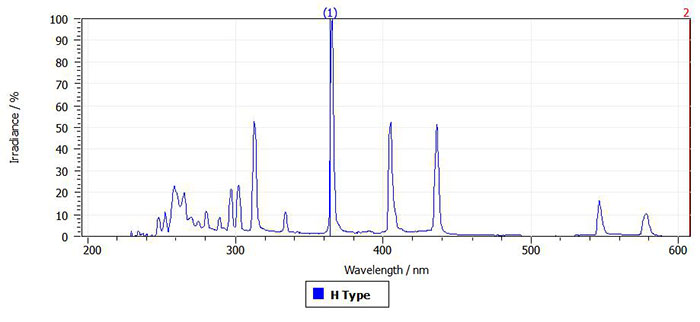

Typical spectrum output of mercury lamp

Typical application: UV curing of inks and varnishes responsive to 365Nm wavelength.

Feature/Application

Mercury capillary lamps provide an intense source of radiant energy from the ultraviolet through the near infrared range. These lamps require no warming-up period for starting or restarting and reach near full brightness within seconds. They come in a variety of arc length, radiant power, and mounting methods, and are used in industrial settings (i.e., for printed circuit boards).

- Optional reflective coating to shorten ignition warm up time

- Optional lamp base – ceramic & metal base with or without power cable along with different terminals.

- Arc length from 80mm up to 2000mm

- Outer diameter from 10mm up to 40mm

- Power density from 40W/cm up to 300W/cm

- UV Curing of Solvent-Free Paints, Coatings, and Adhesives

- Industrial Photochemistry

- Special Applications Such as Ozone Production and UV Analysis

Understanding that each industry has unique requirements, we offer customized

We pride ourselves on our ability to distribute our products efficiently across all continents. We offer comprehensive support services, including installation assistance, operational training, and ongoing technical support, to ensure our clients can fully leverage the capabilities of our

UV Capillary Exposure Lamp

solutions tailored to specific exposure needs. Whether it’s adapting the lamp configuration to different substrate sizes or adjusting the UV intensity for particular types of capillary films, our expertise allows us to meet the precise demands of our clients. Quality assurance is integral to our operations. Each Products undergoes stringent testing to ensure it meets global standards of performance and safety. We also emphasize sustainability in our manufacturing processes, employing environmentally responsible practices and materials to minimize our ecological impact.We pride ourselves on our ability to distribute our products efficiently across all continents. We offer comprehensive support services, including installation assistance, operational training, and ongoing technical support, to ensure our clients can fully leverage the capabilities of our

UV Capillary Exposure Lamp

. That are at the forefront of photolithography technology, providing unmatched precision and adaptability for a variety of industrial applications. With a focus on innovation, custom solutions, and customer support, we continue to lead as a manufacturer and supplier in the UV exposure industry. Trust us to enhance your photolithographic processes with advanced, reliable UV exposure solutions.Enquiry Now

Products List

UV Curing Lamp & Lamp Bases

Typical spectrum output of mercury lamp

Typical application: UV curing of inks and varnishes responsive to 365Nm wavelength.

Medium Pressure Mercury-Arc lamp

TYNGSHUOH TECH produces standard and custom UV Curing Lamps. Our production facility is designed to meet specific customer requirements to produce customized UV lamps, as well as achieve consistent quality in mass production. We design our own production machines with PLC program controller, we are able to optimize our manufacturing process. This results in precision filling technology making our lamps virtually free of impurities, thus preventing early blackening of the lamp. These lamps are components which may be used by customers to manufacture a variety of finished products.

BENEFITS

Consistent quality for small or large quantity production

Precise filling technology

Optional reflective coating to shorten ignition warm up time

Optional lamp base – ceramic & metal base with or without power cable along with different terminals.

Arc length from 80mm up to 2000mm

Outer diameter from 10mm up to 40mm

Power density from 40W/cm up to 300W/cm

APPLICATIONS

UV Curing of Solvent-Free Paints, Coatings, and Adhesives

Industrial Photochemistry

Special Applications Such as Ozone Production and UV Analysis

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文