UV Curing Lamp are specialized light sources designed to emit ultraviolet light, widely used across various industries for applications such as curing, disinfection, and inspection. These lamps are crucial for processes that require precise and efficient UV light exposure.

These lamps are essential in sectors like printing, where they cure inks and coatings; in healthcare, for sterilizing medical equipment; and in water treatment facilities, where they effectively neutralize harmful pathogens without chemicals. Their versatility also extends to the automotive industry for curing body fillers and paints.

These lamps are essential in sectors like printing, where they cure inks and coatings; in healthcare, for sterilizing medical equipment; and in water treatment facilities, where they effectively neutralize harmful pathogens without chemicals. Their versatility also extends to the automotive industry for curing body fillers and paints.

UV Curing Lamp

Selecting the right Industrial UV Lamp involves understanding several key factors:

Wavelength: Different applications require specific UV wavelengths. Ensure the lamp’s spectrum matches your needs.

Intensity and Power: The effectiveness of UV lamps often depends on their intensity and power output. Higher power lamps can expedite processes and penetrate deeper.

Lamp Life: Consider the operational life expectancy of the lamp, as frequent replacements can increase downtime and costs.

Q: What safety precautions are necessary when using

A: Proper shielding and protective gear are essential to protect against UV exposure, which can be harmful to skin and eyes.

Q: How energy efficient are

A: Many newer models are designed to be energy efficient, but efficiency can vary widely between different types.

The industry is seeing significant advancements in UV LED technology, which offers longer life spans and reduced energy consumption compared to traditional mercury vapor UV lamps. This shift is driving greater adoption in industries focused on environmental sustainability and operational efficiency.

The manufacturing of UV Lamps involves sophisticated technology and strict quality control processes to ensure reliability and effectiveness. Top manufacturers and suppliers invest heavily in research and development to improve lamp performance and develop new applications for UV technology.

UV Lamps are indispensable tools in numerous sectors, providing essential services that range from curing and drying to sterilization and inspection. With ongoing advancements in technology and a shift towards more sustainable practices, these lamps continue to evolve, offering greater efficiency and utility across industries.

Wavelength: Different applications require specific UV wavelengths. Ensure the lamp’s spectrum matches your needs.

Intensity and Power: The effectiveness of UV lamps often depends on their intensity and power output. Higher power lamps can expedite processes and penetrate deeper.

Lamp Life: Consider the operational life expectancy of the lamp, as frequent replacements can increase downtime and costs.

Q: What safety precautions are necessary when using

UV Curing Lamp

?A: Proper shielding and protective gear are essential to protect against UV exposure, which can be harmful to skin and eyes.

Q: How energy efficient are

UV Curing Lamp

?A: Many newer models are designed to be energy efficient, but efficiency can vary widely between different types.

The industry is seeing significant advancements in UV LED technology, which offers longer life spans and reduced energy consumption compared to traditional mercury vapor UV lamps. This shift is driving greater adoption in industries focused on environmental sustainability and operational efficiency.

The manufacturing of UV Lamps involves sophisticated technology and strict quality control processes to ensure reliability and effectiveness. Top manufacturers and suppliers invest heavily in research and development to improve lamp performance and develop new applications for UV technology.

UV Lamps are indispensable tools in numerous sectors, providing essential services that range from curing and drying to sterilization and inspection. With ongoing advancements in technology and a shift towards more sustainable practices, these lamps continue to evolve, offering greater efficiency and utility across industries.

Discover Advanced Solutions with UV Curing Lamp

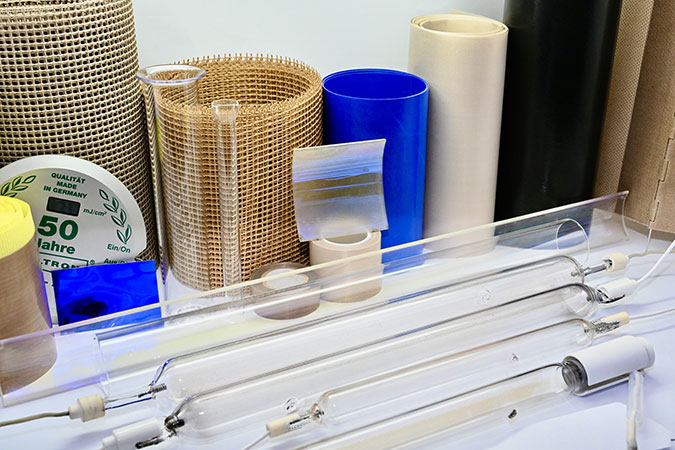

Unlock efficiency in diverse sectors with our UV Curing Lamp. Each UV Metal Halide Lamp enhances manufacturing precision, while our UV Curing Lamp expedites drying processes for faster production cycles. The Fusion UV Lamp is crafted for endurance and consistent UV exposure, supported by essential components like the UV Quartz Tube and UV Reflector which focus and intensify the UV light effectively.

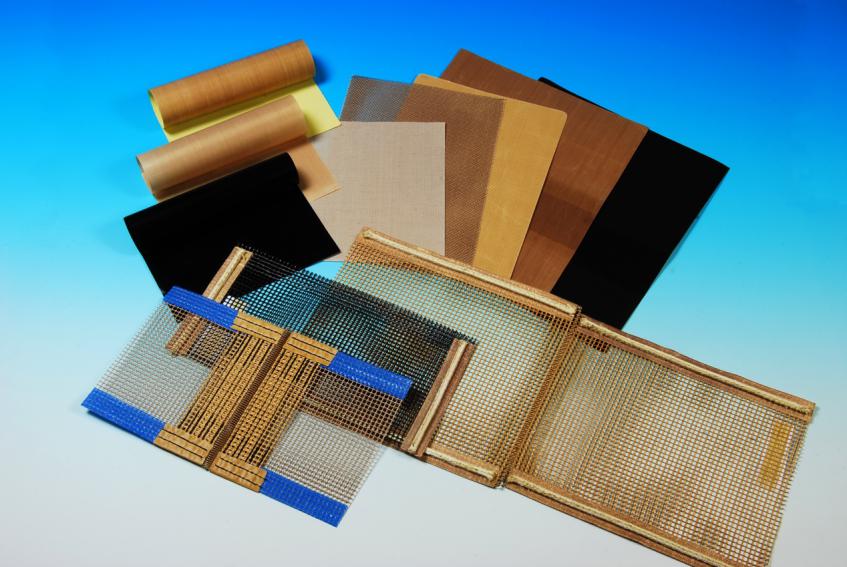

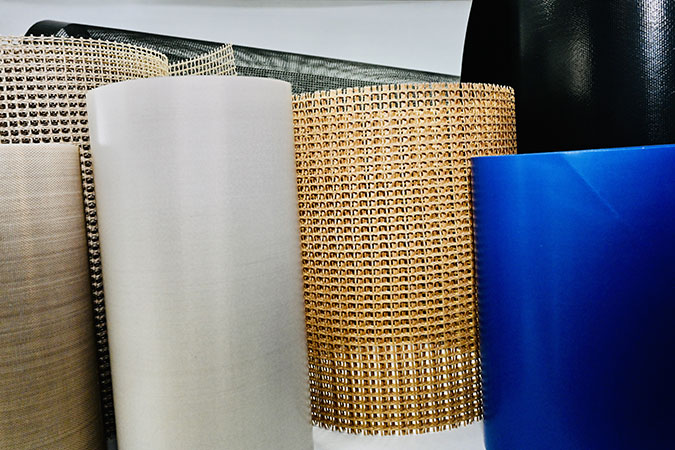

Our UV Mirror directs UV light with precision, and the UV Lamp Power Supply maintains stable power for optimal lamp performance. Monitoring with a UV Meter ensures the correct intensity for perfect results every time. In material handling, our PTFE Conveyor Belt and advanced Teflon Belt Joint Process Method deliver robust, long-lasting solutions. The PTFE Heat Sealing Belt is designed for high-temperature resilience, complemented by Conveying Belt Joint Process Equipment and Conveying Belt Process Accessories that enhance belt functionality.

For sealing and insulation, rely on our PTFE Adhesive Tape and PTFE Coated Fiberglass Fabric, engineered for durability and resistance in challenging environments. Choose our products for comprehensive solutions that blend innovation with reliability, ensuring superior performance across various industrial applications.

Unlock efficiency in diverse sectors with our UV Curing Lamp. Each UV Metal Halide Lamp enhances manufacturing precision, while our UV Curing Lamp expedites drying processes for faster production cycles. The Fusion UV Lamp is crafted for endurance and consistent UV exposure, supported by essential components like the UV Quartz Tube and UV Reflector which focus and intensify the UV light effectively.

Our UV Mirror directs UV light with precision, and the UV Lamp Power Supply maintains stable power for optimal lamp performance. Monitoring with a UV Meter ensures the correct intensity for perfect results every time. In material handling, our PTFE Conveyor Belt and advanced Teflon Belt Joint Process Method deliver robust, long-lasting solutions. The PTFE Heat Sealing Belt is designed for high-temperature resilience, complemented by Conveying Belt Joint Process Equipment and Conveying Belt Process Accessories that enhance belt functionality.

For sealing and insulation, rely on our PTFE Adhesive Tape and PTFE Coated Fiberglass Fabric, engineered for durability and resistance in challenging environments. Choose our products for comprehensive solutions that blend innovation with reliability, ensuring superior performance across various industrial applications.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文