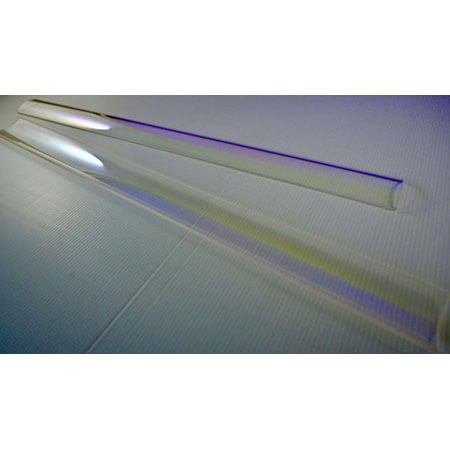

Quartz Plate

We are proud to introduce our superior quality products, meticulously designed to meet the diverse needs of modern industries. As a leading manufacturer and supplier, our commitment is to deliver quartz solutions that excel in both performance and reliability. Our Quartz Plate is crafted from pure, high-grade quartz, renowned for its optical clarity and high thermal stability. This makes it an ideal choice for a wide range of applications, including high-temperature viewing windows, semiconductor fabrication, and UV light filtration. The inherent properties of quartz ensure superior durability and resistance to thermal shock and chemical corrosion, providing our clients with a dependable product that withstands rigorous industrial environments.

Quartz Plate

Model - QGRDF/3T*48.5W*580L

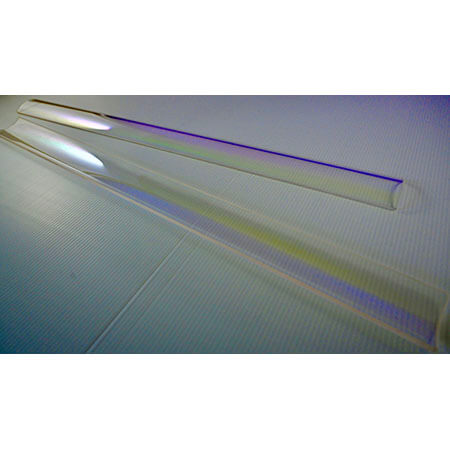

Curved Cold Mirror (Reflector)

Dichroic film coating glass reflector

Spectral characteristics:

Reflecting avg. ≧92% for spectrum range at 220~400Nm

Transmission avg. ≧ 80% for spectrum range at 450~2000Nm

The reflectors we produce help reflect the ultraviolet curing energy and pass infrared wavelengths. This is achieved by reflecting visible light. Less infrared radiation means less heating of the illuminated object in the beam. Dichroic reflectors are used in compatible lamps to help the system dissipate heat and thereby extend the life of the lamp.

Dichroic film coating glass reflector

Spectral characteristics:

Reflecting avg. ≧92% for spectrum range at 220~400Nm

Transmission avg. ≧ 80% for spectrum range at 450~2000Nm

The reflectors we produce help reflect the ultraviolet curing energy and pass infrared wavelengths. This is achieved by reflecting visible light. Less infrared radiation means less heating of the illuminated object in the beam. Dichroic reflectors are used in compatible lamps to help the system dissipate heat and thereby extend the life of the lamp.

Understanding the critical need for precise specifications in industrial applications, we offer customized

As a global supplier, we ensure that our

Quartz Plate

solutions tailored to meet the exact requirements of our clients. Whether you need specific dimensions, thicknesses, or finished edges, our skilled team is equipped to provide high-precision cuts and finishes to match any demand, ensuring seamless integration into any system or process. Our manufacturing processes forQuartz Plate

incorporate the latest technological advancements to enhance efficiency and reduce waste. We are committed to sustainable practices, using environmentally friendly techniques that minimize our carbon footprint and promote resource conservation. This dedication to innovation and sustainability not only enhances the quality of our products but also aligns with our clients' values and regulatory requirements.As a global supplier, we ensure that our

Quartz Plate

products are readily available to clients worldwide. We support our products with a comprehensive package of services, including expert consultation, technical support, and after-sales service. Our experienced team is always ready to assist, from initial design and customization to installation and maintenance, ensuring optimal performance and satisfaction. Our products set the standard for quality and innovation in the industry. With a focus on custom solutions, technological advancement, and environmental responsibility, we are the trusted partner for companies seeking superior quartz products. Choose our expertise for your quartz needs and experience unmatched quality and service.Enquiry Now

Products List

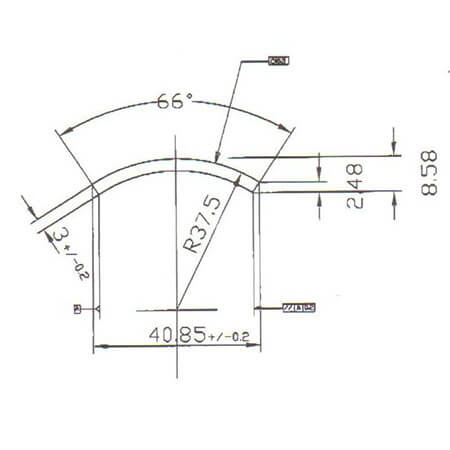

UV Curved Dichroic Coating Reflectors/Cold Mirrors

GCTC’s aluminum and cold mirror reflectors are suitable for standard UV systems for which substrate to use is depending on the characteristics of the working piece; Cold-mirror reflectors are using for heat-sensitive materials as they absorb heat-producing infra-red energy and reflects only the UV energy.

UV Curved Quartz Dichroic Reflectors

UV cold mirrors reflect UV energy while removing heat-producing visible and infrared energy. The removal of visible and infrared energy can be accomplished by transmitting the visible and infrared energy through the reflecting optic (typically fused silica) or by absorbing the visible and infrared energy and transferring the absorbed heat to the reflecting optic (typically aluminum). UV cold mirrors are extremely effective at increasing the amount of reflected UV energy at the irradiation zone while simultaneously significantly reducing the visible and infrared energy. The result is lower temperatures at the irradiation zone, allowing the processing of temperature sensitive substrates.

Cold mirrors are useful in protecting temperature sensitive substrates. Uses include

Photo polymerization of inks, dyes and adhesives

Semiconductor manufacture

Printed circuit board manufacture

Product packaging

Flooring

Water sterilization

Imaging

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文