UV Cold And Hot Mirror

As a leader in optical technology, we are proud to offer the UV Cold And Hot Mirror, a revolutionary product designed to enhance the efficiency of lighting systems while protecting sensitive components from heat damage. As a trusted manufacturer and supplier, we are dedicated to providing high-performance optical solutions that meet the evolving needs of our clients across various industries. Our engineered to reflect UV and infrared (IR) light while allowing visible light to pass through. This dual functionality makes it an ideal component for applications requiring precise light filtration, such as in photography, solar simulation, and scientific instruments. The mirror's ability to effectively manage heat and UV exposure protects equipment from potential damage and extends its operational life.

UV Cold And Hot Mirror

Model - Hot Mirror/Quartz Plate

Hot Mirror/Quartz Plate

Technical Data

GCTC’s hot and cold mirrors are ideal for use in situations where heat could severely damage an experimental setup. The dichroic coating glass mirrors are available in various sizes. Our UV fused silica mirrors offer increased transmission and reflectance, a lower coefficient of thermal expansion.

The quartz plate is generally place between the lamp and the substrate. The plate does not absorb UV rays but enhance in reradiating the rays at a temperature lower than the working lamp. It is necessary to clean the plate regularly for better performance of the curing results. GCTC provide the products of the top-most quality.

A normal glass plate cannot withstand extreme temperatures as much as a quartz plate does. UV lamp helps in drying inks and graphic coatings. The main use of a quartz plate in the lamp is to prevent the accumulation of debris, dirt and contaminants from building in the filter.

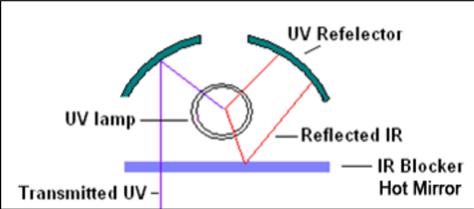

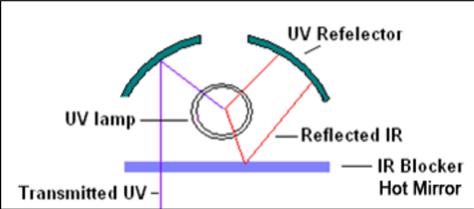

The UV hot mirror is primarily placed to reduce the effect of infrared rays (IR) that may have an effect over the printing clarity. Along with dichroic reflectors, the hot mirrors improve UV energy and reduce infra-red energy that can cause a likely damage to certain substrates that are heat sensitive. By directing the IR energy to the filament, the hot mirror helps by giving you a better printing experience by providing you a reliable way of removing heat.

The replacement lamp is used to dry coatings and inks in signs and graphics and is an important component of the drying system. The UV curing lamp is a better option than infra-red drying as it resists smudges. The quartz plate protects lamps from debris and works as a filter between lamp and the curing system. The plate prevents dirt, grit and contaminants from building up.

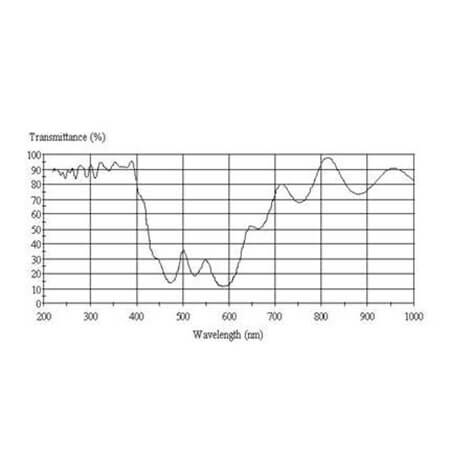

Technical Data

- Tavg > 85%: 220-400nm

- Tavg < 30%: 430-630nm

- Tavg <= 87%: 700-2500nm

GCTC’s hot and cold mirrors are ideal for use in situations where heat could severely damage an experimental setup. The dichroic coating glass mirrors are available in various sizes. Our UV fused silica mirrors offer increased transmission and reflectance, a lower coefficient of thermal expansion.

The quartz plate is generally place between the lamp and the substrate. The plate does not absorb UV rays but enhance in reradiating the rays at a temperature lower than the working lamp. It is necessary to clean the plate regularly for better performance of the curing results. GCTC provide the products of the top-most quality.

A normal glass plate cannot withstand extreme temperatures as much as a quartz plate does. UV lamp helps in drying inks and graphic coatings. The main use of a quartz plate in the lamp is to prevent the accumulation of debris, dirt and contaminants from building in the filter.

The UV hot mirror is primarily placed to reduce the effect of infrared rays (IR) that may have an effect over the printing clarity. Along with dichroic reflectors, the hot mirrors improve UV energy and reduce infra-red energy that can cause a likely damage to certain substrates that are heat sensitive. By directing the IR energy to the filament, the hot mirror helps by giving you a better printing experience by providing you a reliable way of removing heat.

The replacement lamp is used to dry coatings and inks in signs and graphics and is an important component of the drying system. The UV curing lamp is a better option than infra-red drying as it resists smudges. The quartz plate protects lamps from debris and works as a filter between lamp and the curing system. The plate prevents dirt, grit and contaminants from building up.

Understanding the diverse needs of our customers, we offer

Our reach extends far beyond our headquarters, ensuring that our

UV Cold And Hot Mirror

that can be customized to specific dimensions, shapes, and spectral requirements. Whether you need a standard size for general use or a bespoke design for a specialized project, our team is equipped with the expertise and technology to deliver products that fit your exact needs. Quality is at the core of our operations. Each products is manufactured using the highest quality materials and undergoes rigorous testing to ensure peak performance and durability. Our commitment to innovation is reflected in our continuous improvement of manufacturing processes and investment in research and development, which allows us to stay at the forefront of the optics industry.Our reach extends far beyond our headquarters, ensuring that our

UV Cold And Hot Mirror

are available to clients around the world. We support our products with extensive services, including technical support, installation guidance, and maintenance tips. Our dedicated customer service team is always ready to assist you in making the most of our advanced optical solutions. The testament to our dedication to excellence and innovation in optical technology. With our mirrors, you can enhance the functionality and longevity of your lighting systems, ensuring they perform optimally while withstanding the challenges of heat and UV exposure. Choose our expertise for your optical needs and benefit from the best in technology and service.Enquiry Now

Products List

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文